Casting operations

Careful work with proficient skill

There is a variety of work within a casting factory. There is the separation of scrap parts from products after they are casted by pouring molten metal into a mold, welding work where we use our welding technology for gas welding of defective areas which are unrelated to the function of the products, milling cutter operation to rough process the products, and other work all of which requires unique technology and proficiency.

The technicians employed by our company have sufficient knowledge and skill while also working hard to study and increase their skills day by day. Utilizing the achievements and experience accumulated over many years, we can meet a wide array of customer needs from improvement of product quality to cost reduction and more.

Points of Shohosha's "casting operations"

Line contract

We handle operations in 3K workplaces in casting operations which tend to be avoided for being "dangerous(kiken)", "dirty(kitanai)", and "hard(kitsui)". We employ many casting technicians who are highly skilled in welding repair and other processing duties. We also use the achievements and experience we have accumulated over many long years to make proposals regarding product quality improvement, cost reduction, etc.

Casting work

- ・Repair of heat-resistant material on the inside of the mold vessels into which molten metal is poured from the cupola

- ・Removal of sulfur which is mixed into the moten metal

- ・Repair of chutes through which moten metal flows from cupola

- ・Transport of molten metal from cupola to workplace for pouring

- ・Removal of other metals stuck within the cupola via lance rod

- ・Removal of runners and burrs using a variety of hammers depending on the product material and thickness

- ・Division of labor enables us to conduct detailed work even in assembly-line operation

- ・Drafting of work manual when new parts flow in

- ・Implementation of work in accordance with our customer's needs

- ・After shaking out, remove sand, etc. stuck to the cast metal

- ・Overlay welding repair of defective areas which are unrelated to the function of the products

- ・Periodic inspection of gas welding

- ・Acquisition and renewal of welders' certifications

- ・Inspection of spots to be welded by microscope and durometer

- ・Measurement of preheat and postheat with thermochalk and laser heat measurement

- ・Use a variety of air tools to accurately finish the parts which were overlaid with gas welding

- ・Everything up to the removal of burrs and sand, grinder, and pneumatic blast, and inspection

- ・Removal excess thickness with a milling machine specialized disc

- ・Can grind to height 500 mm, width 1200 mm, front and rear 300 mm

- ・Straightening and chill disassembly via heat treatment

- ・Coating of products after finishing work

For these kinds of clients

- Searching for contractors who can handle the casting process comprehensively

- Considering contracting the work in a casting factory

- Searching for proficient welders

- Want to reduce production costs for cast products

- Trouble with high turnover rate due to 3K workplace

- Want contractor to handle product quality management of cast products as well

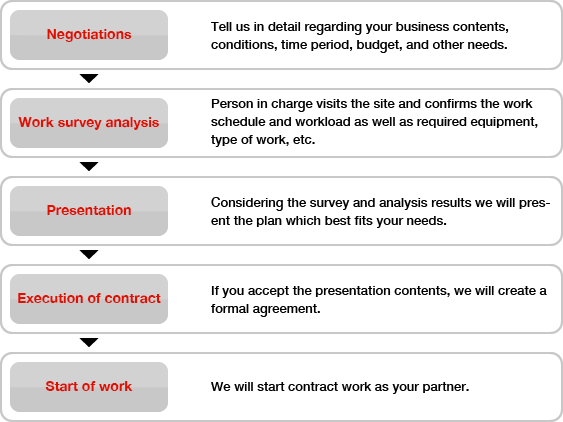

Flow up to start of work

Example of work

Casting plant (Nihonmatsu-shi, Fukushima)

We are contracted to handle a variety of work involving casting in the customer's plant including welding repair, finishing, gate cutting, etc. The job is hard and also requires proficiency, but we strive to train and increase our skills day by day.

Casting plant (Kitakami-shi, Iwate)

We handle milling work, welding repair work, and other metal processing work. This work requires proficiency.